2-Way GE3 Series

An Environmentally Friendly Solution that Satisfies Your Requirements

Please Select Your User Type

Specs

Maximum 60 HP combination

Domestic Hot Water (DHW) priority setting

Operating range in heating down to -21°C and up to +24°C for air to water system

No defrost cycle

Capacity ratio: 50-200% (16-25 HP), 50-170% (30 HP)

Combination capacity ratio: 50% of smallest outdoor unit capacity - 130% of total capacity of outdoor unit combination

Documents

Combination

Indoor Unit

Centalised Controller

Accessory

Case Studies

Features

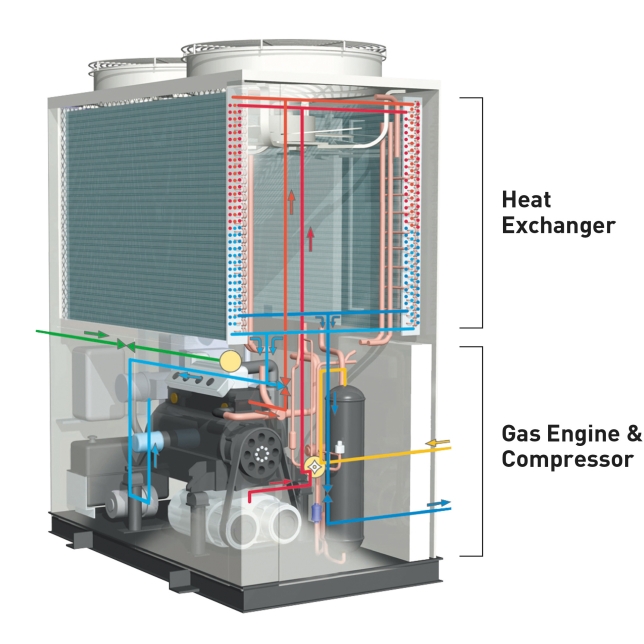

What is GHP?

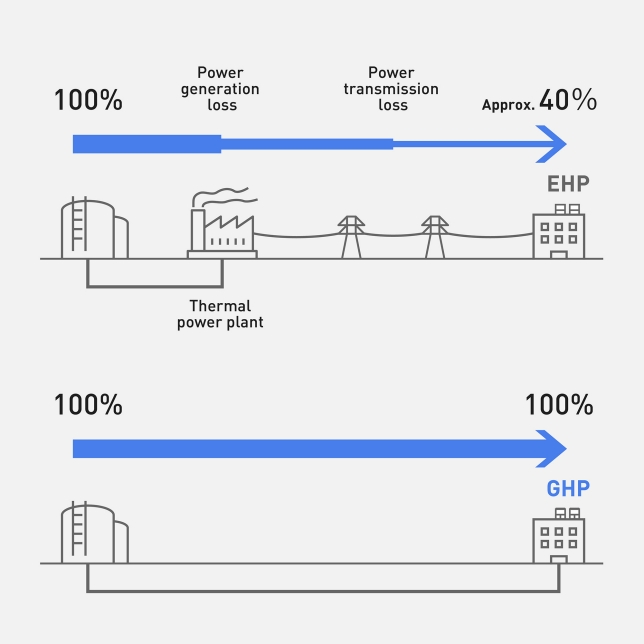

Cost Reductions through Use of a Gas Engine

Significantly Reduced Power Consumption

Significant Cuts in Power-Receiving Equipment Costs

Waste Heat from Gas Engines can be Used for Domestic Hot Water (DHW)

High Efficiency through Trustworthy Design and Technology

1 High Blast Efficiency

2 L-Shape Heat Exchanger

3 Exquisite Partial Load Control

Mechanisms for High Operational Efficiency and Energy-Saving Performance

Improved Engine Torque Results in Reduced Energy Costs

Increased Engine Pulley Diameter for Higher Efficiency

Improved Compression Efficiency through an Upgraded Compressor

Environmentally Friendly

Low Environmental Impact

Low CO₂ Emissions

Low NOx Emissions

Up to 64 Indoor Units can be Connected