What is Cell Cultivation?

What is Cell Cultivation?

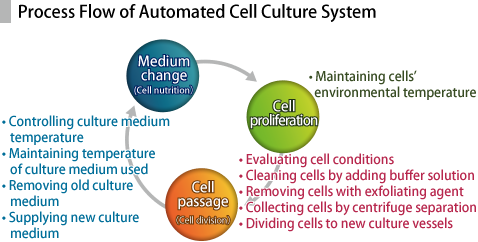

- Changing culture medium daily

Suctioning and removing old culture medium, without peeling off cells, and adding new culture medium - Conducting cell passages every few days

Uniformly disseminating proliferated cells into multiple culture vessels according to desired size and density

- Changing culture medium daily

Suctioning and removing old culture medium, without peeling off cells, and adding new culture medium - Conducting cell passages every few days

Uniformly disseminating proliferated cells into multiple culture vessels according to desired size and density

Automated cell culture system that continuously supplies cells

Automated cell culture system that continuously supplies cells

Basic Functions for Automating Cell Culturing Processes

Basic Functions for Automating Cell Culturing Processes

Clean cabinet

Clean cabinet

HEPA filter keeps clean and safe environment equivalent to class II safety cabinet

HEPA filter keeps clean and safe environment equivalent to class II safety cabinet

Incubator

Incubator

Max. 60 100-mm dishes (or max. 27 6-well plates) can be stored in CO2 incubator

Max. 60 100-mm dishes (or max. 27 6-well plates) can be stored in CO2 incubator

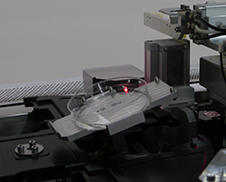

Dispensing & Swinging

Dispensing & Swinging

Special 10mL pipette is suitable for separating cells. Swing equipment to blend suspension in a dish.

Special 10mL pipette is suitable for separating cells. Swing equipment to blend suspension in a dish.

Refrigerator & Warmer

Refrigerator & Warmer

Refrigerators can store Max. 4 500-mL bottles at 4°C. Warmers are provided to warm liquid temporarily.

Refrigerators can store Max. 4 500-mL bottles at 4°C. Warmers are provided to warm liquid temporarily.

Cell observation

Cell observation

Deep-learning AI technology leveraged to find cells’ conditions or count cell number

Deep-learning AI technology leveraged to find cells’ conditions or count cell number

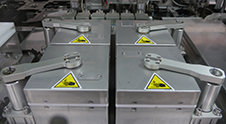

Centrifuging

Centrifuging

A centrifuge is implemented for automated cell passage. Considering its effect on cells, it's placed far from the incubator.

A centrifuge is implemented for automated cell passage. Considering its effect on cells, it's placed far from the incubator.

Advantages of New System

Advantages of New System

Automating manual techniques

Automating manual techniques

Reproducing techniques by thoroughly analyzing manual work and utilizing proposed manipulation control technique

Reproducing techniques by thoroughly analyzing manual work and utilizing proposed manipulation control technique

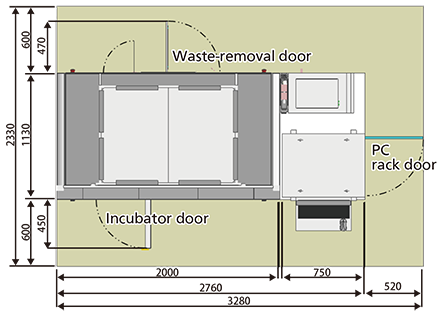

Compact size

Compact size

Achieved a compact size that easily fits into laboratories by designing a structure that is interchangeable with a standard clean bench

Achieved a compact size that easily fits into laboratories by designing a structure that is interchangeable with a standard clean bench

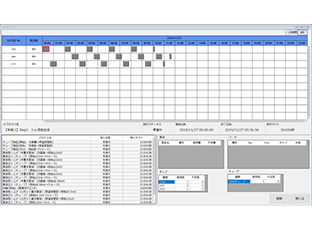

Scheduling

Scheduling

Automatically conducting preset movements and maintaining history records of each culture vessel

Automatically conducting preset movements and maintaining history records of each culture vessel

Specification

Specification

Cultivating process | Culture medium change, cell passage, cell observation |

|---|---|

Target cell | Adhesive cell: ES/iPS cell (colony/single cell), etc. |

Heat insulation | 4-500ml bottles |

Culture vessel | Max. 60 Φ100-mm dishes (or max. 27 6-well plates) can be stored |

Dedicated supplies | 10mL pipettes (Max. 100 bottles) |

Cultivation plan | Cultivating process can be set using scheduling function |

Biohazard | Cabinet class II equivalent (Clean 100 equivalent within the unit) |

Decontamination | UV irradiation, peracetic acid fumigation |

Cell observation | Image storage, passage timing determination, cell count |

Main unit dimensions | W 2,000 x D 1,130 x H 2,412 mm |

Utilities |

|

Cultivating process | Culture medium change, cell passage, cell observation |

|---|---|

Target cell | Adhesive cell: ES/iPS cell (colony/single cell), etc. |

Heat insulation | 4-500ml bottles |

Culture vessel | Max. 60 Φ100-mm dishes (or max. 27 6-well plates) can be stored |

Dedicated supplies | 10mL pipettes (Max. 100 bottles) |

Cultivation plan | Cultivating process can be set using scheduling function |

Biohazard | Cabinet class II equivalent (Clean 100 equivalent within the unit) |

Decontamination | UV irradiation, peracetic acid fumigation |

Cell observation | Image storage, passage timing determination, cell count |

Main unit dimensions | W 2,000 x D 1,130 x H 2,412 mm |

Utilities |

|