Environment

In order to achieve both "a better life" and "a sustainable global environment," Panasonic Industry is using a variety of our device technologies to develop products with the lowest possible environmental impact, helping to realize carbon neutral societies and a circular economy toward the aim of reducing the burden on our environment.

Panasonic Industry Environmental Initiatives Video

Strengthen Environmental Initiatives

Panasonic Industry is focused on achieving its Environmental Vision through working steadily to solve environmental issues affecting society. We are further speeding up the pace of efforts to combat the urgent issues of climate change and resource depletion as prime concerns to realize a society with a minimal impact on the global environment.

Panasonic Industry's Environmental Vision

In order to achieve both “a better life” and “a sustainable global environment”, we will lead the progress of civilization with a variety of device technologies.

Together with our customers we will realize a society that has a minimal impact on the global environment.

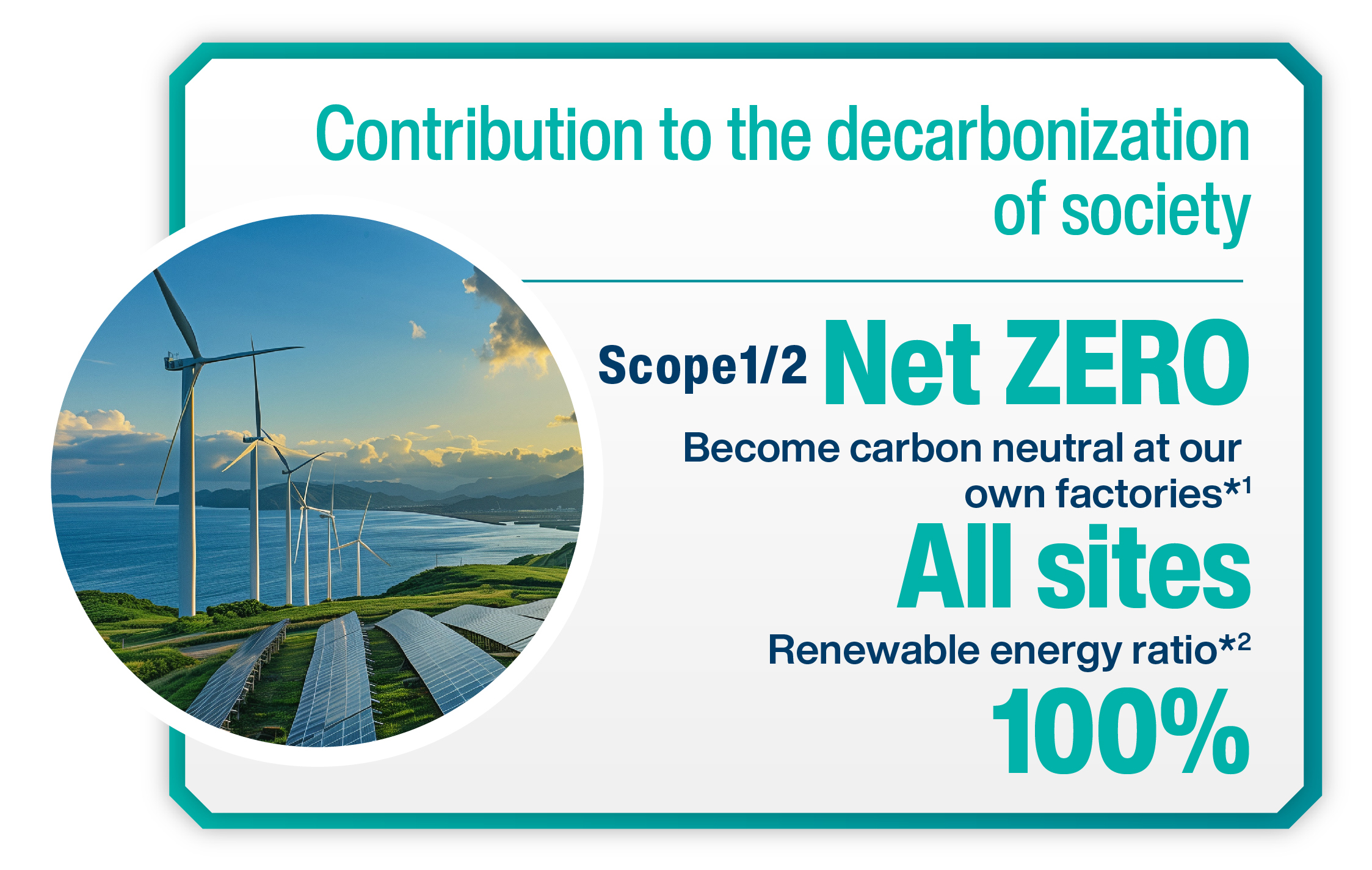

2030 Target and KPI

*1 Factories that have achieved net-zero CO2 emissions through energy saving and the introduction of renewable energy, along with the use of power certificates and CO2 credits.

*2 Percentage of electricity, fuel, etc. used by Panasonic Industry that is derived from renewable energy sources (includes certificates, credits, and other externally procured items)

*3 Factory waste recycling rate = Amount of resources recycled / (Amount of resources recycled + Amount of landfill)

Panasonic Industry's Environmental Initiatives

Global Warming Prevention

Resource Recycling

Environmental Performance Data

Highlights of Our Initiatives

Aiming at net zero CO2 emissions*4 in our production activities by 2030

CO2 emissions from factories will be cut through promotion of energy saving and use of renewable energy, to achieve carbon neutral manufacturing. We have set target to achieve net zero CO2 emissions in each region, and our aim is to achieve net zero CO2 emissions for all our manufacturing sites globally by 2030.

*4 Achieving net-zero CO2 emissions through energy saving and the introduction of renewable energy, along with the use of power certificates and CO2 credits

Contributing to lower environmental impacts through evolution of product performance

We are proactively seeking to develop and provide compact, lightweight, low loss and high durability products with minimal environmental impact in our broad lineup.

Weight reduction

Motors for industrial application

20% reduction compared to the previous model

We have achieved the highest speeds and torque in the industry in our MINAS A6 series of AC servo motors used in production machinery and industrial robots while reducing their weight by 20% (750 grams) compared to the previous model.

High heat resistance

Multi-layer circuit board materials

Support for lead-free soldering

In our MEGTRON® series of multi-layer PCB material for ICT infrastructure equipment we are using lead-free solder with high heat resistance and a high melting point compared to previous types.

Long life at high temperatures

Conductive polymer capacitors

3x the previous model

For our SP-Cap® JX series of electroconductive polymer aluminum electrolytic capacitors we have achieved product life at high temperatures three times longer than previous products. In addition, by replacing multilayer ceramic capacitors with this product, we can realize more compact equipment taking up a smaller space.