Lineup

Specification

Here is our all kinds of UA3P. We will introduce feature and specification.

1. Standard equipment

UA3P-300

UA3P-400

2. Large-scale equipment

UA3P-500H

UA3P-550H

UA3P-650H

UA3P-700H

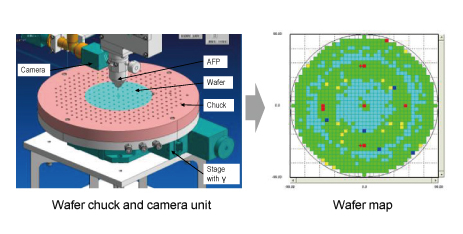

3. Top-surface and Side-surface profilometer ( Twin probe )

3. Top-surface and Side-surface profilometer ( Twin probe )

UA3P-400T*1

4. High-accuracy equipment

UA3P-3100

UA3P-4000

UA3P-5000H

*1: • This product is categorized as a product (or technology) that qualifies as a regulated cargo as specified by the Foreign Exchange and Foreign Trade Act.

• To export or transfer abroad applicable products (or technology) ,you must gain permission for export in advance from the Japanese government.

*2:Includes shape error of the standard sphere

*3:According to our measurement regulations

*4:Wind from air conditioners should not directly blow onto the equipment

*5:EU Data Act

- Transparency Notice

- Data specification

Ultrahigh Accurate 3-D Profilometer(UA3P Series)

UA3P Specifications List

Option

UA3P options for measuring a wide range of shapes

Hardware

Mechanics options | Details | |

|---|---|---|

1 | Auto Tilt Stage (2 Axis, 3 Axis) | Mechanism that automatically corrects the tilt of a measuring object based on its measured data. |

2 | Wafer Chuck & Stage | Adding an air chucking stage and recognition camera for wafer lens measurement. |

3 | Decenter and Tilt measuring Jig (various types) | Jig used for decenter and tilt measurement (used in combination with option software [9]) |

Stylus for top-surface measurement

Top Diamond Stylus R 2 D 60

(PED-16100112)

Top Ceramic Stylus R 500 μm

(PED-1610M079)

Top Diamond Stylus R 2 D 60 (L=12mm)

(PED-16100116)

Top Diamond Stylus R 2 D 45 (EM)

(PED-1610M106)

Top Diamond Stylus R 2 D 30

(PED-1610M052)

Top Diamond Stylus R 5 D 45

(PED-1610M077)

Stylus for side-surface measurement

Side Ruby Stylus φ2 mm

(PED-1630M020)

Side Ruby Stylus φ 1 mm

(PED-1630M021)

Side Ruby Stylus φ 300 μm

(PED-1630M022)

Side Ceramic Stylus φ 1 mm (L=30mm)

(PED-1630M035)

Side Carbide Stylus φ 80 μm

(PED-1630M024)

Side Carbide Stylus φ 30 μm

(PED-1630M025)

Decenter and Tilt measurement jig

Decenter/Tilt measurement between lens faces

The lens is fixed on a jig provided with three reference balls for combination. Any decentering between the lens faces is evaluated by measuring both faces of the lens.

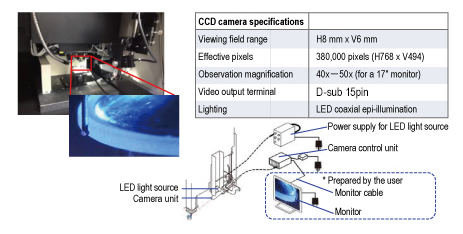

Observation camera

Applicable model: All models

A measuring point is magnified for display to enable easy positioning.

Wafer level lens (WLL)

Applicable model: UA3P-500H/650H/700H

* Precautions

*1 Note that the ruby stylus is at risk of breaking due to its large coefficient of friction while measuring aluminum lenses or surface-coated lenses.

*2 The stylus for side-surface measurement (Φ30 µm - Φ300 µm) may require an observation camera for measurement.

◆ In addition to the contents described, we prepare a variety of stylus, such as different size and material. Please contact our sales for detail.

Software

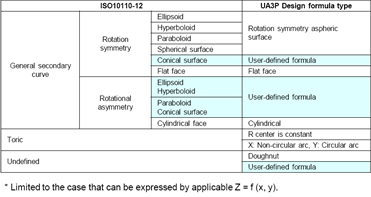

Software Option | Details | |

|---|---|---|

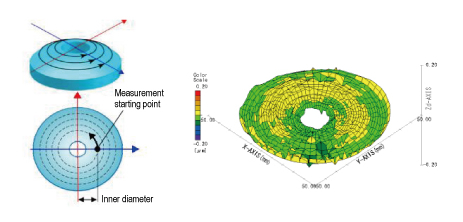

1 | Circular scanning measurement function | Adds circumferential scanning NC paths for measured objects with a hole in the center. |

2 | Top Flat centering function | Function that enables centering of a measuring object whose center is nearly flat. |

3 | User-defined formula function | Function to evaluated by user created formula. |

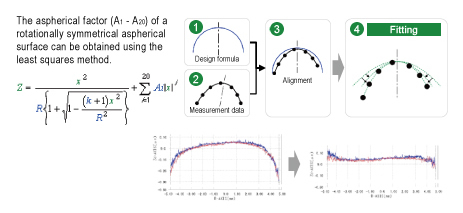

4 | Aspherical coefficients fitting function | Function to fit aspherical coefficients based on measured data. |

5 | Diamond stylus correction function | Function to correct stylus tip shape based on standard sphere measured data. |

6 | Point cloud data design formula creation function | Function to generate a spline curved formula based on points cloud converted from CAD data (provided by the customer) |

7 | One million data points sampling, captureing 2000 points per second function | Function to expand the number of measurement points and to increase the speed of capturing data points. |

8 | Waveguide software (offline) | Function to evaluate the dimensions of the shape of an object based on the measured data. |

9 | Decenter and tilt evaluation software (offline) | Function to evaluate decenter and tilt of lens front and back using the jig installed 3 sphere. |

10 | Automatic Measurement Software | Function to create measurtement procedure program and to execute procedures automatically. |

11 | Wafer lens measurement software | Function to measure and evaluate wafer lenses in combination with mechanical option [2] |

Circumferential scanning measurement software

The measured object is circumferentially scanned and measured.

- Hollow objects are also measureable.

- Up to 1200 concentric circles.

User-defined software (free-form curved surfaces, etc.)

Other formulae are supported in addition to the lens design formula that is registered as a standard feature.

The use of the C language for creating the design formula and the calculation part of a partial differential equation allows all of ISO10110-12 to be covered.

Software for creating point group data design formula

A rectangular curved surface is created using the spline function with respect to given 3D point group data.

Fitting software (rotation symmetry)

A previously unknown design formula of a measured object can be obtained from the measurement data.

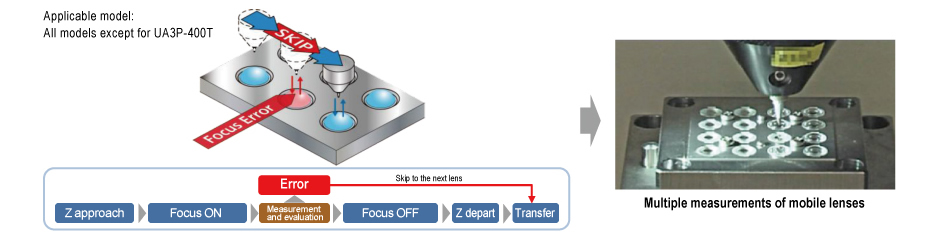

Auto-measurement

Applicable model: All models except for UA3P-400T

Fully automated, including probe movement and focus ON/OFF

Supporting various errors

* The jig is prepared by the user

Contact

Contact us for any question about the UA3P.